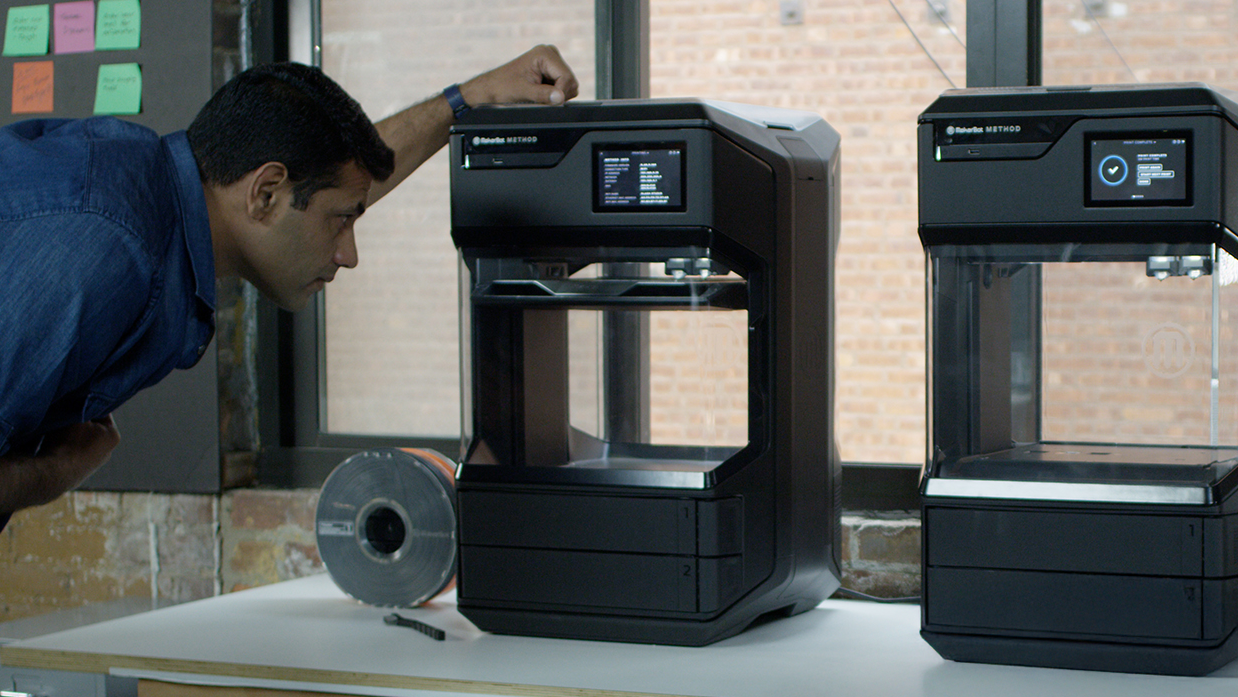

MakerBot Method

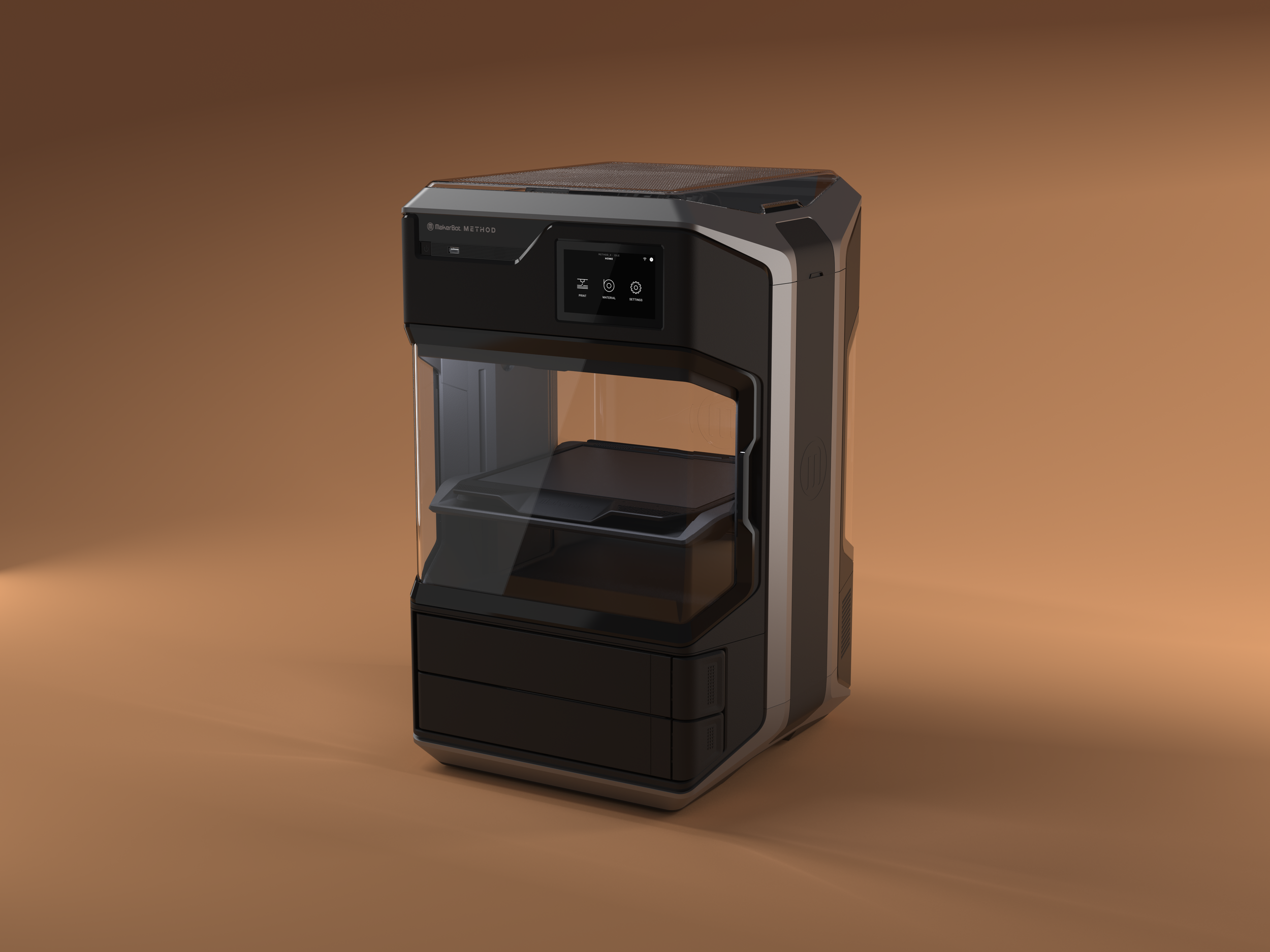

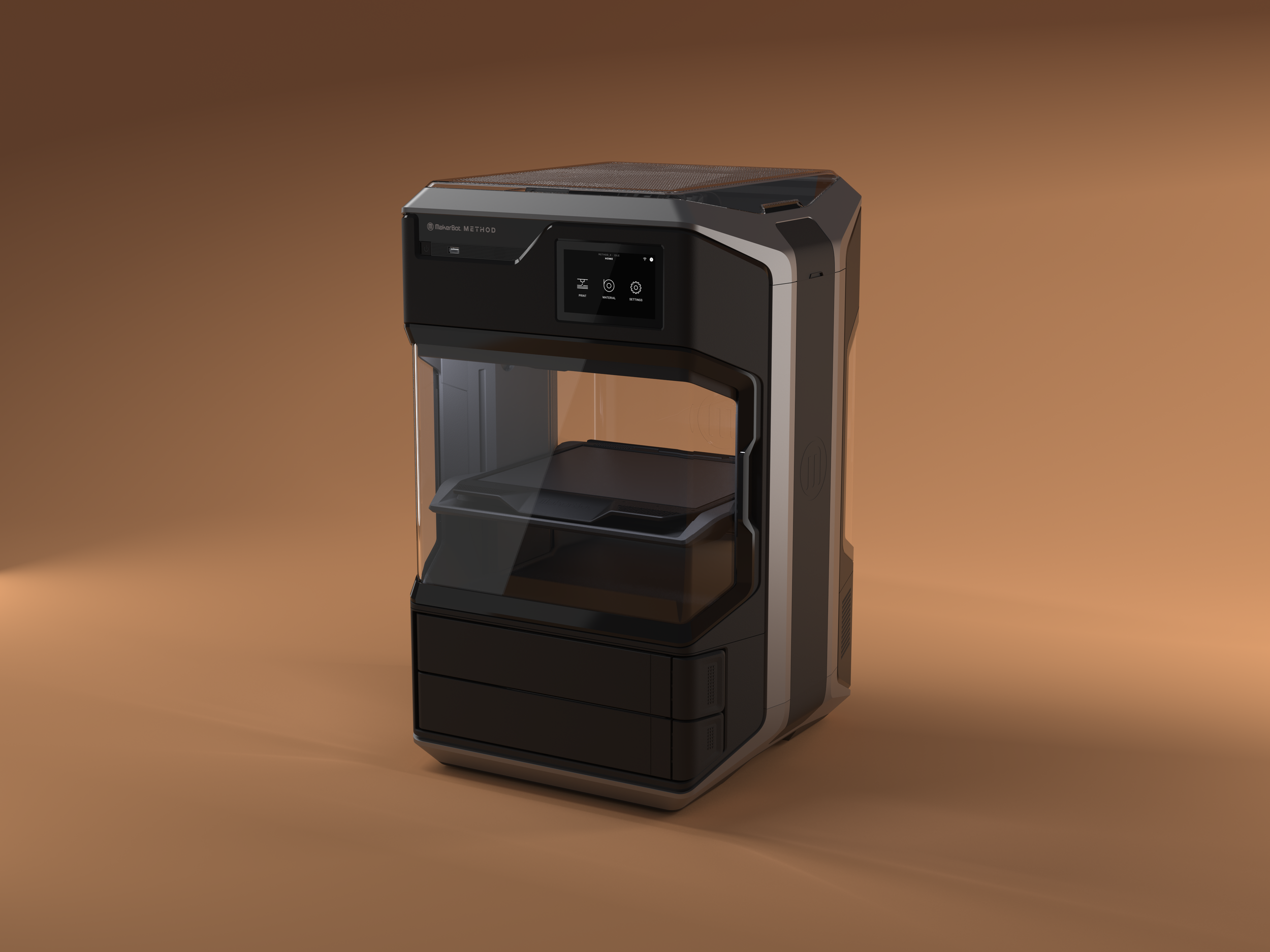

The MakerBot Method was developed with professional makers at the forefront. With the 5th Generation 3D printers, MakerBot captured the general public’s interest and began its foray into the educational space. However, professional makers had yet to truly invest in desktop 3D Printers. Leveraging the MakerBot’s acquisition by Stratasys, we were able to learn, design, and built a system that did just that. The MakerBot method was a robust 3D printer with top line engineering and design, that ultimately dominated the low end of Stratasys’s line up of professional 3D Printers.

My Role

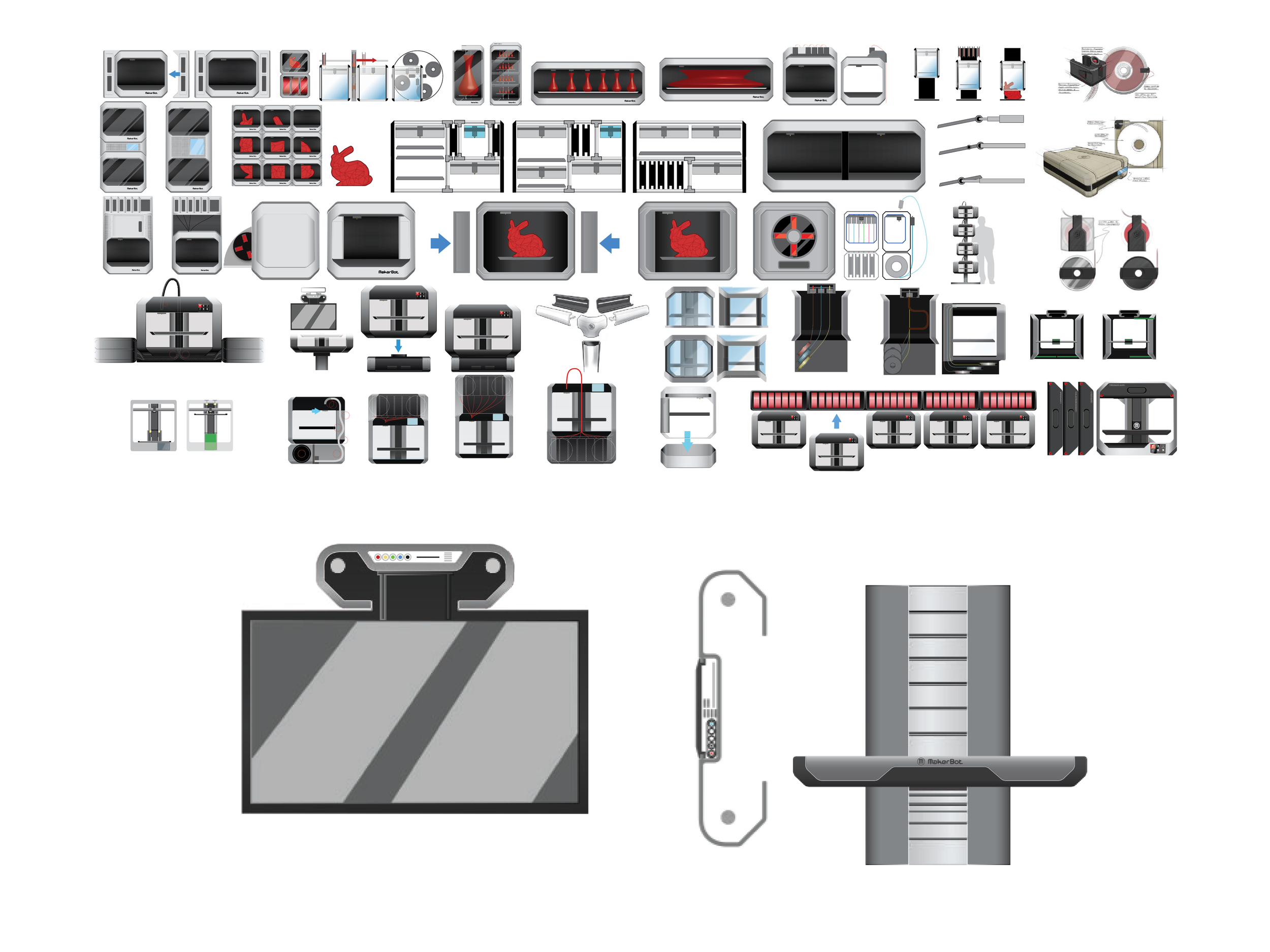

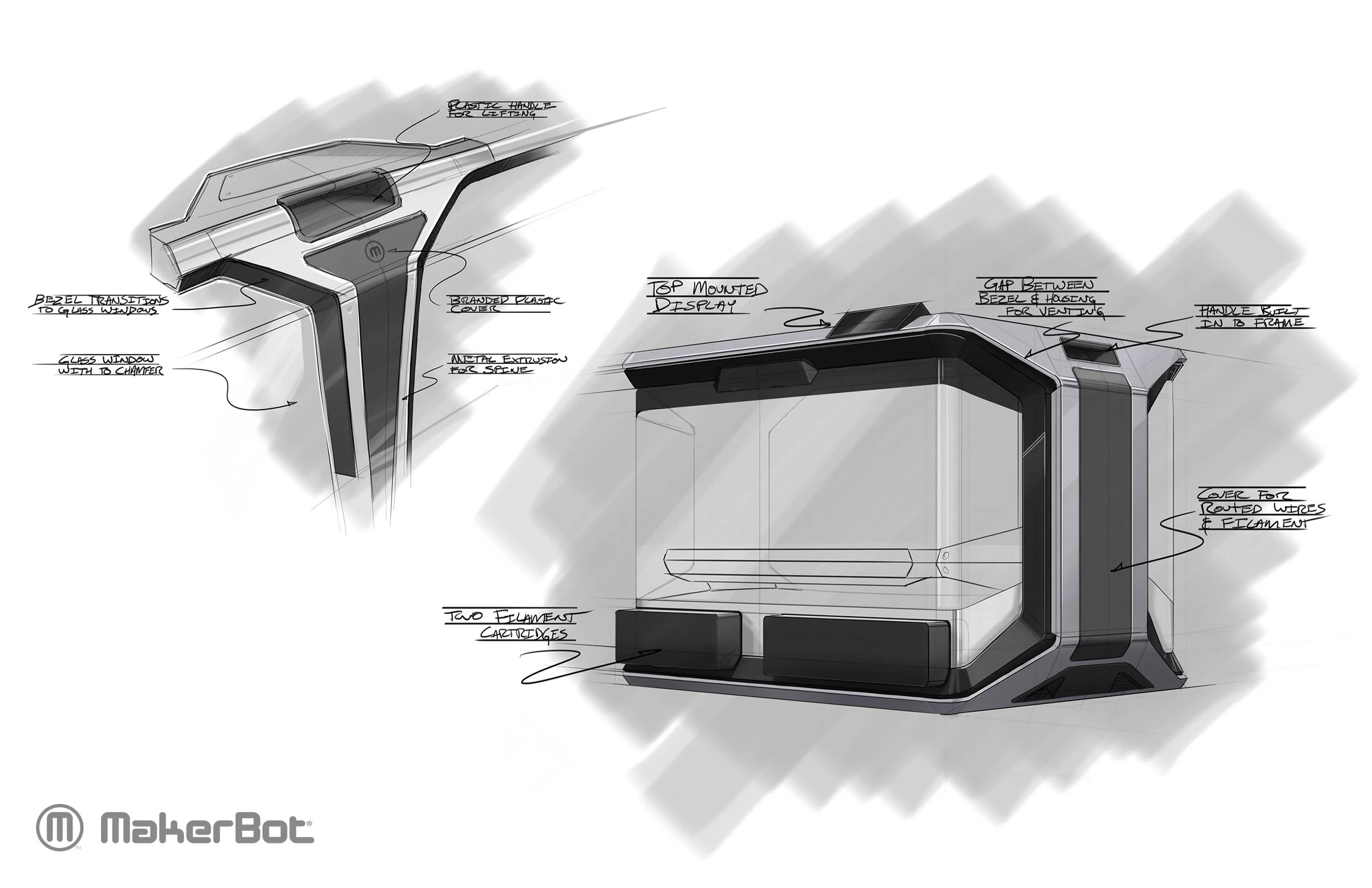

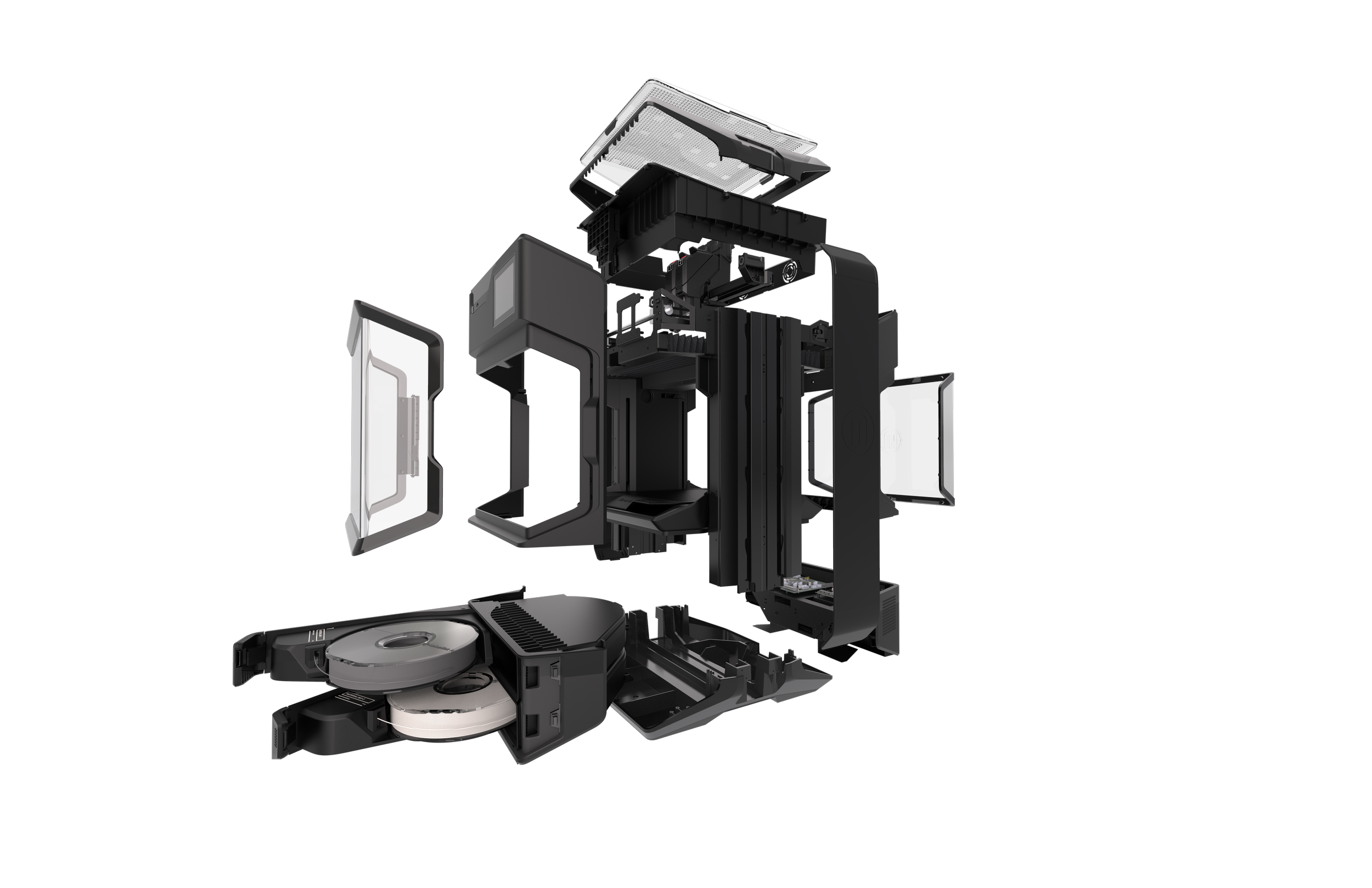

The Industrial Design team got a head start conceptualizing what the future of desktop professional 3D Printing could be. From stacking designs to modular gantry systems. At this time, I developed both function focused concepts to form studies, all while working closely with the engineering team.

Watching the mechanical engineers build chassis out of T-slot aluminum extrusions, I realized the potential of using custom extrusions to add visual form, wire routing, and structural integrity. This realization lead to many concepts, including the final design of the MakerBot Method.

During development, I designed all exterior and interior housings for the 3D Printer in close collaboration with the housings mechanical engineer.